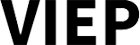

Introduction of multi-purpose steamed bun production line

The flour of the multi-purpose steamed bun production line is poured into the dough mixer and water is added in proportion. Controlled by the microcomputer, the conveyor belt transports the dough into the continuous noodle press. After several times of rolling, conveying, and passing through the slope conveyor Segmentation, conveying, and then roll the noodles through the knife-cut steamed bun forming machine, and the rolled noodles are pinched and broken by the kneading machine, and then rounded for the second time to ensure that the proofing and steaming process of the product will not be affected.

Features of multi-purpose steamed bun production line:

1. Automatic dough kneading and automatic conveying can reduce labor costs, improve production efficiency, reduce labor intensity of operators, and have a high degree of automation.

2. Adopt continuous pressing surface. Make the gluten structure of the dough embryo not to be torn and destroyed, form a layered gluten, and keep the gluten network complete and uniform.

3. Making full use of microcomputer programming control and photoelectric induction technology to replace manual operation, the weight of steamed buns is more accurate, easy to use and high in accuracy.

4. Reasonable design, compact structure, simple use and convenient maintenance.

5. The size of the product is uniform, the surface is smooth, and the taste is pure.

6. The parts in contact with food are made of high-quality stainless steel and PE or PTFE materials, which meet the national food hygiene standards.

Main functions of automatic steamed bun production line:

1. The thickness and width of the noodle strips after shaping are more compatible with the subsequent noodle forming equipment

2. The electric eye controls the speed to prevent the main engine from being broken or blocked due to too fast delivery speed

3. The rolling wheel and the auxiliary rolling wheel roll the dough into strips

4. The length and weight of the product; with synchronous stepless speed regulation function

5. more convenient to operate

6. The production line can be changed flexibly (that is, different products can be produced with different peripheral equipment)

Technical parameters of the steamed bun production line

Model: SLB-4800G

Output: 4800 steamed buns/hour, 1000~8000 steamed buns/hour

Finished product weight: 15-80g/pc

Power: about 6kw

Dimensions: 6830×1250×1500mm

Machine weight: about 1060 kg